Looking after the launder

It needs fettlin'!

As the Heron’s June newsletter says, a launder is “a chute or trough for holding or conveying water”. Our launder conveys water from the River Bela into the mill and drops it on the waterwheel. All that lovely clean, green, renewable energy!

The same technique of diverting river water could be used to “launder” the ore from your mine, or wash your clothes. And it seems that in the 16th century you had to be alert when dealing with washer women and millers alike, as they were not above pinching some of your washing or your grain when your back was turned.

1570 In washing by hand, haue an eye to thy boll, For Launders and millers be quicke of their toll.

A miller might hold back a peck (9 pounds) of meal from every boll (140 pounds) he milled for you. Meanwhile the odd shirt or a pair of socks might go missing out of a load of washing.

One of the main reasons the launder is in need of fairly regular maintenance work is that it provides practically ideal conditions for plants of all kinds to grow. Plenty of water, not many passing gardeners, and lots of nice wooden planks expanding and contracting, making nooks and crannies for weeds to get established in.

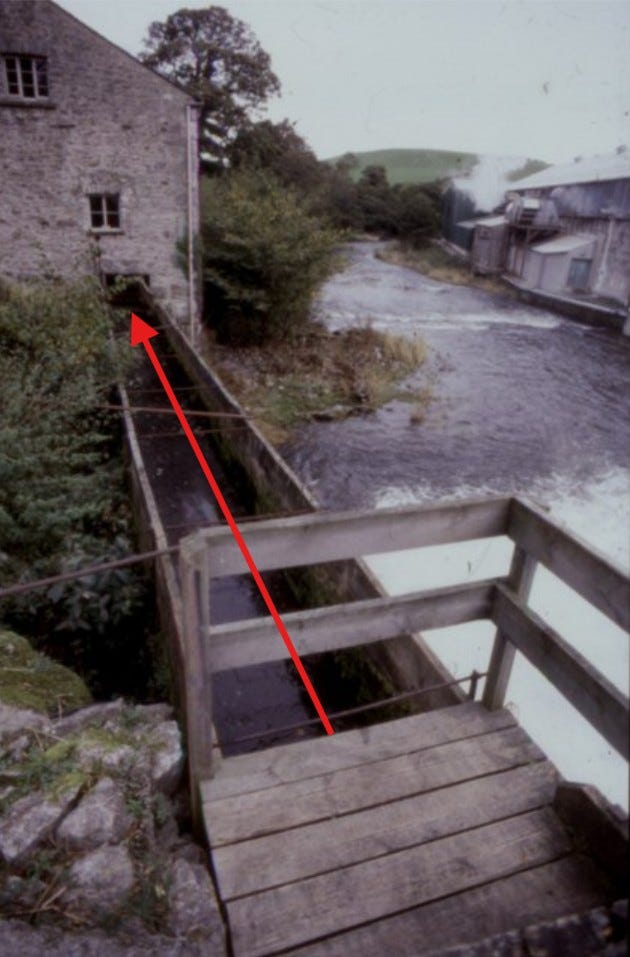

Where the launder crosses over the fish pass, you can see plenty of water escaping from the bottom.

The launder has a gate at the top to let water in; at the bottom to let water out into the mill; and an escape gate part way up to let water escape if the miller is not ready for it. You can see the escape gate in this picture, just next to the mill -

This arrangement gives a surprising degree of fine-tuning of the water supply to the mill - one more example of practical design and problem solving by generations of millers and millwrights.

Stuart and Steve have a lot of work to do on the launder. They need to identify any wood that needs replacing due to rot, and source suitable replacement wood. Even choosing what type of wood to use is a big decision. Getting it wrong could result in the repairs lasting years rather than decades! Then how tight should the planks be? They will expand and shrink through the seasons, so there is a balance to be struck. And how vigorously to weed the cracks? There may be some pointing between the planks to be done with burnt sand mastic, like you’d use to seal round window frames.

We visited Warwick Bridge Mill recently. Their set up is quite a lot different from the Heron mill, and at first I didn’t even recognise their launder. There is no wooden structure to maintain, just the space between two rows of houses. When the escape gate is open (as in this picture) the water cascades magically down a set of steps off to the left and through the mill garden, rejoining the river lower down. When the gate is closed, the water continues straight ahead to the mill and onto the water wheel.

Warwick Bridge Mill are hoping to restore a set of stones for cracking the shells off oats. This will allow them to make their own rolled oats from raw oats rather than from pre-shelled ones, which they reckon are less tasty. This project is going to involve some input from the Near Far Heron project, of which more next time.

Thank you Stuart and Steve not only for all the work needed to keep the mill operational , but also for your knowledge and expertise you so willingly share and pass on.